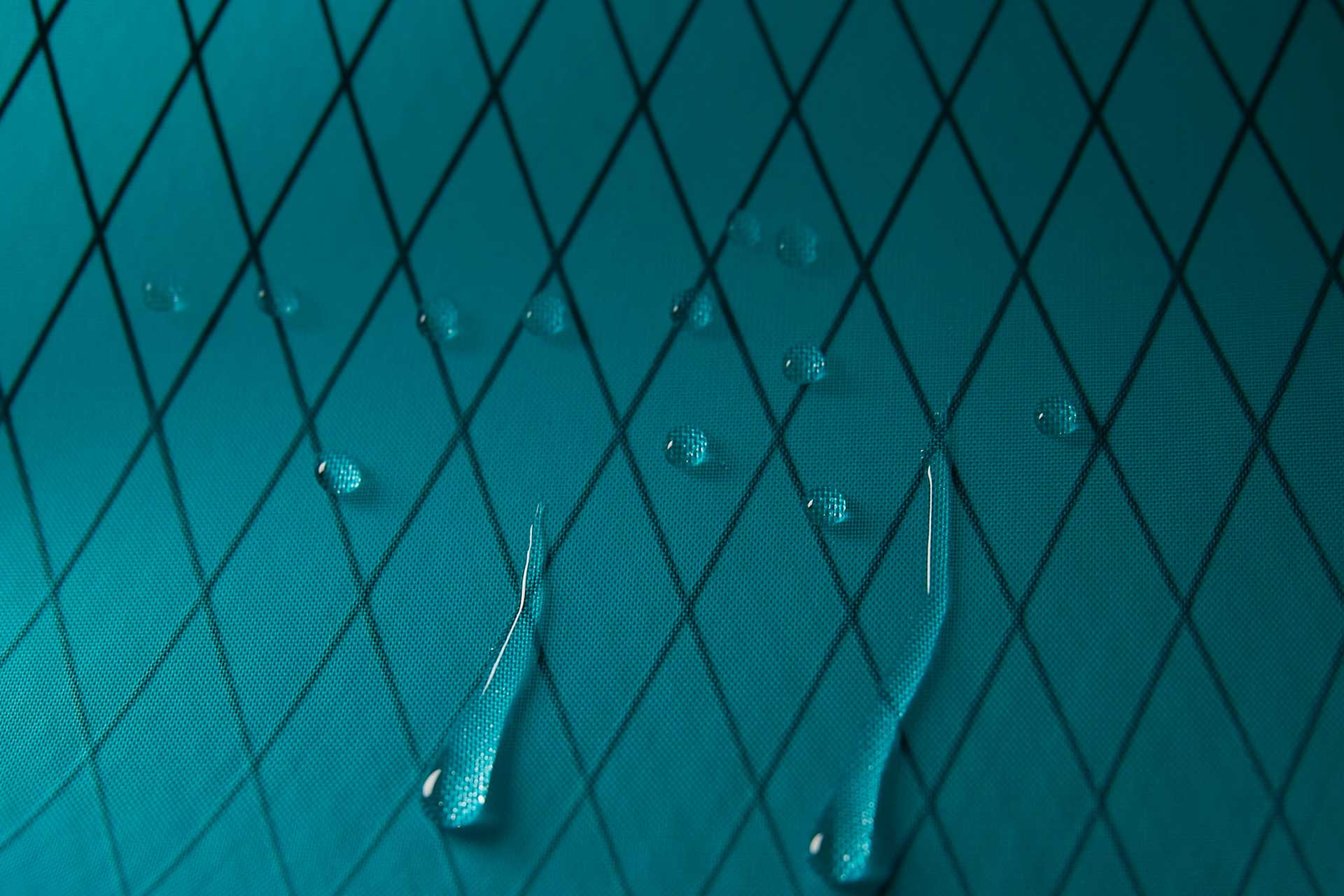

There are obvious wrinkles on the surface, which belong to a completely waterproof material with tear resistance. The waterproof film is sandwiched in the middle, and without the film, there is no problem of peeling off the waterproof layer.

Also known as "silicone coated nylon", many lightweight coverings are made of silicone coated nylon cloth. Silicified nylon fabric and silicon treated nylon are both referring to this type of fabric. Remember, silicone nylon coating is highly flammable.

Dali Ma is a synthetic fiber produced by a Dutch company DSM Research and development. It is a kind of UHMWPE( The product name of ultra-high molecular weight polyethylene (UHMWPE) fiber in the United States is Spectra。 The fabric is extremely lightweight but has characteristics such as tear resistance and low water absorption. The texture of the fabric will become more and more pronounced and wrinkled with increasing use.

Cause UHMWPE( Made by mixing and weaving ultra-high molecular weight polyethylene, it has the characteristics of lightweight, high strength, UV resistance, etc. Recently, more and more packaging styles have been explored Ultra texture of material.

On a heavier frame backpack, the two shoulder straps should not be too close together, as it can cause compression on the shoulders, neck, and trapezius muscles, resulting in weight-bearing pressure. Consider making curved shoulder straps to alleviate this issue, and carefully consider the physical behavior of the backpack under typical loads, as it may experience severe deformation.

Elastic rope, trapezoidal lock, rope lock, and side opening buckle. The world of various plastic fixing device expansion accessories is very vast and worth exploring.

Lightweight backpacks have almost no carrying system to save weight (compared to traditional heavy backpacks), and each brand's approach to strengthening the weight-bearing effect on the back is also different. A common way for lightweight backpackers to carry is to fix the eggshell board on their back and use it flexibly.

When the belt is pulled apart, the widest gap may be close to 3 cm, Internally, there is a movable and adjustable waistband. The benefits of this design can be imagined. When the connected mesh with the back panel moves, air convection introduces the gap area of the waistband, making it easier for this type of Anti-Gravity The breathability of the waistband is more advantageous than traditional waistbands, as it can continuously introduce airflow circulation for breathability.

This is the most difficult material to find. The mesh used for the side bag should be strong, tear resistant, and elastic enough, but not too elastic to avoid collapsing under heavy pressure. It is worth noting that some mesh fabrics have elasticity in one direction but not in another, which needs to be taken into account when cutting and positioning mesh panels.

Ribbon generally has Nylon and Poly Two types. Nylon The quality of the woven tape is good, with a soft touch, and it is only used for premium bags. Most bags use it Poly For lightweight backpacks, 20mm nylon webbing is a good choice.

A good tightening system can balance both external attachments and contraction. Lightweight backpacks with lighter and softer fabrics make it possible to compress through ropes. The same fabric issue results in the shape of the backpack being more dependent on packaging techniques and the effectiveness of the shrinkage system.

The compression system plays an important role in ultra lightweight backpacks. Better compression: The upper, middle, and lower three-stage compression system uses a retractable top cover, side compression bands, and bottom snap fasteners to compress capacity, making it easier to grasp the center of gravity of the backpack.

The strength of a backpack depends on its weakest part. The weakest part is the seam, especially the connection between the shoulder strap and the main backpack. The seams of the backpack are all tightly stitched, making them less likely to tear when carrying heavy loads, while also making the backpack look more sturdy and durable. High quality lightweight backpacks typically combine stitching with waterproof threads and other sealing methods to ensure that the stitched parts remain waterproof.