1. Innovation DNA: Beyond Trend-Following to Market Leadership

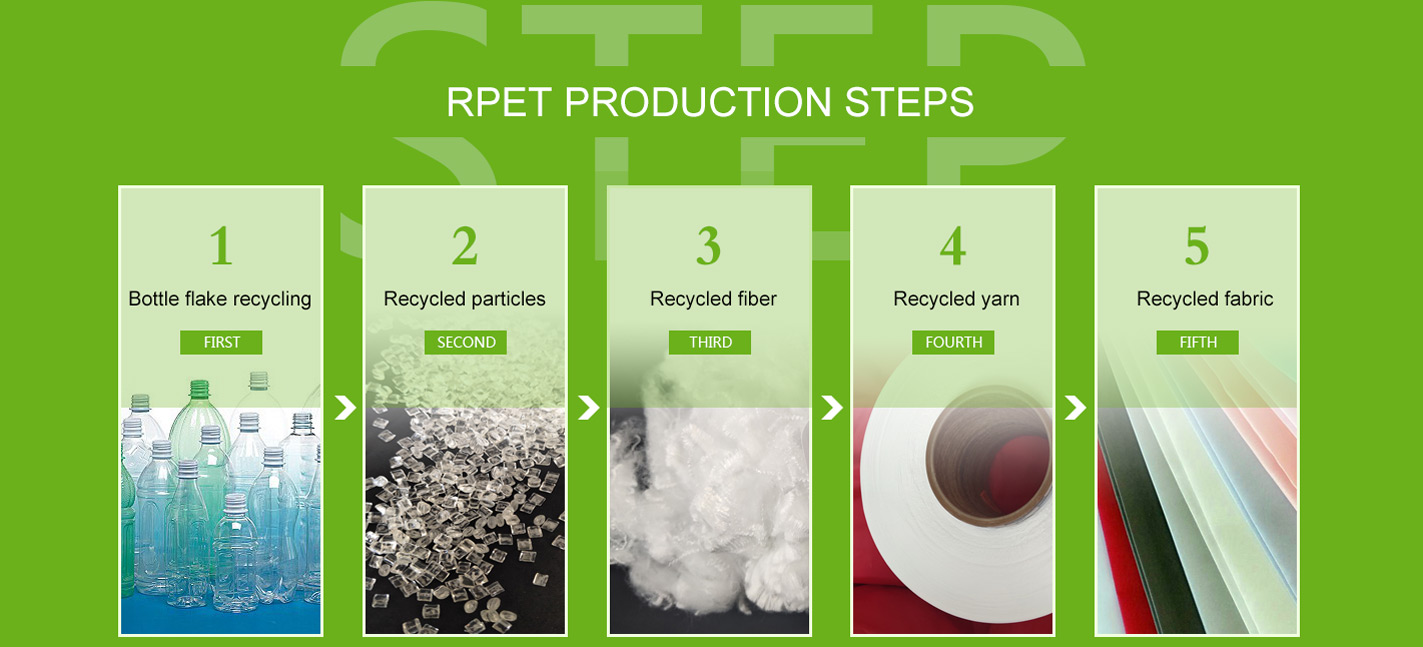

A factory’s innovative capacity is the golden key to unlocking market differentiation. Prioritize suppliers who actively invest in sustainable material R&D (e.g., mushroom-based vegan leather, ocean-recycled PET fabrics) rather than merely replicating existing designs. Scrutinize their design patent portfolio and participation in industry expos like Lineapelle. For instance, cutting-edge factories now integrate smart luggage tech - built-in GPS trackers or self-charging USB hubs - which can elevate your brand’s premium positioning. Request prototypes demonstrating proprietary techniques like heatless embossing or zero-waste pattern cutting to verify true innovation capacity.

2. Workshop Reality Check: Decoding Quality at Source

While advanced machinery like CNC laser cutters indicates technical prowess, the human factor remains irreplaceable. Schedule unannounced visits to observe craftsmanship rituals: How artisans handle edge-painting (minimum 8-layer coating for luxury bags), align grain patterns across panels, or inspect stitch density (12-14 SPI for premium leather goods). Verify their equipment maintenance logs - poorly calibrated machines cause alignment errors in zipper installation. Pro Tip: Request stress-test videos of sample products, particularly for waterproof backpack manufacturing, where seam sealing quality determines market longevity.

3. Leadership Ethos: From Transactional to Strategic Partnership

A CEO’s engagement level predicts your project’s priority ranking. During negotiations, gauge their vertical integration understanding - can they explain tannery partnerships or metal hardware plating processes? Elite manufacturers assign dedicated innovation managers to client accounts, offering material science consultations. For example, Italian luggage leaders like Piquadro factory teams include ex-fashion house technicians who advise on heritage craft techniques like hand saddle-stitching.

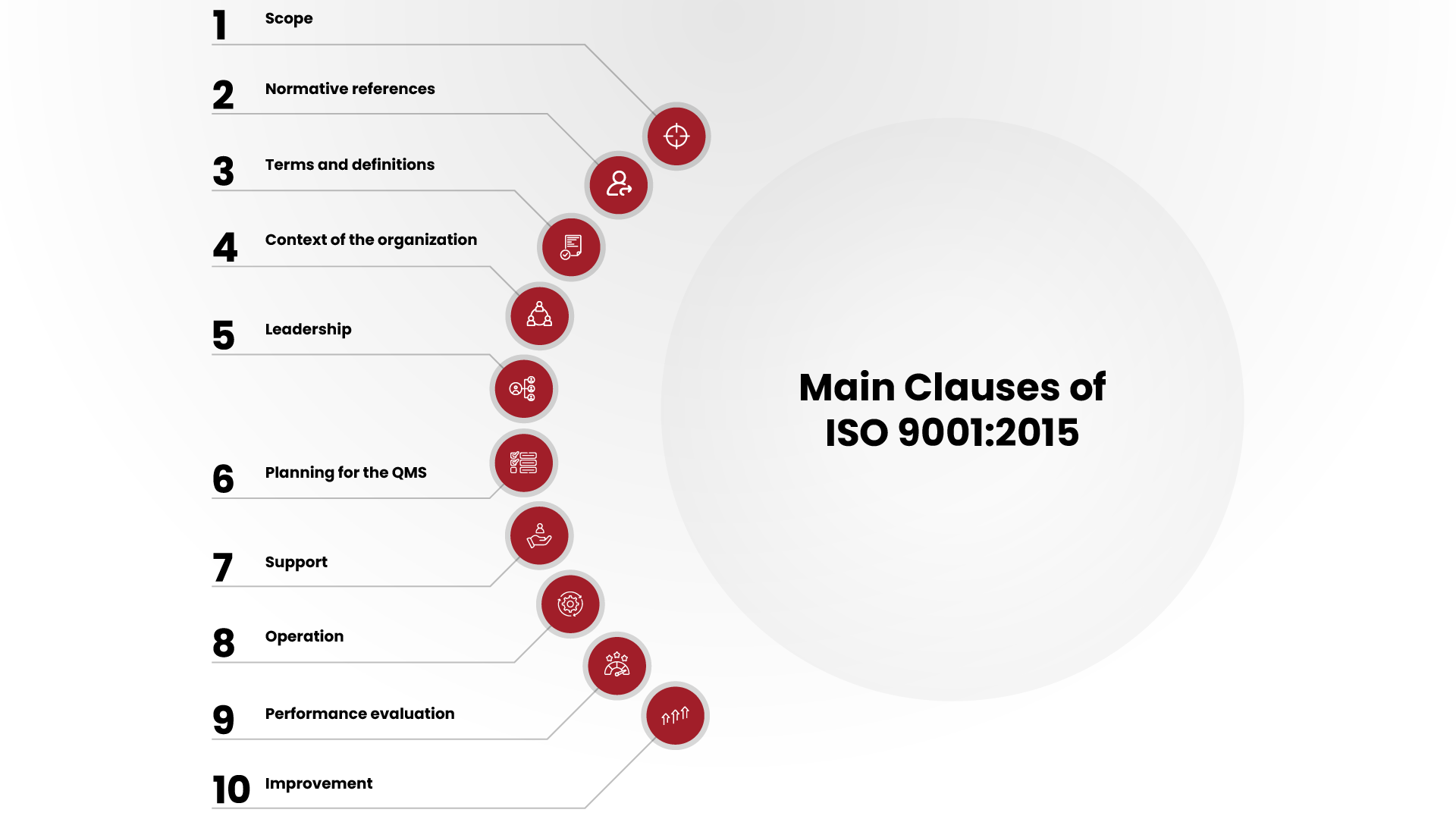

4. QC Architecture: Certifications vs. Practical Implementation

Move beyond basic ISO 9001 claims. Demand granular quality protocols:

Raw Material: Certificate traceability (e.g., Leather Working Group audits for eco-tanned hides)

Final Inspection: 360° checklist including colorfastness (48-hour UV exposure tests), hardware load cycles (5,000+ tests for luxury briefcase clasps)

Smart brands now require factories to implement blockchain-enabled QC documentation, creating immutable quality records for conscious consumers.

5. Ethical Production Transparency: The New Competitive Edge

Modern buyers demand radical supply chain visibility. Vet factories through third-party social accountability audits (SA8000/WRAP certified) confirming:

Fair wage practices exceeding local minimums by 25%+

Chemical management systems eliminating PFAS/PFCs from waterproofing processes

Forward-thinking manufacturers like Guatemala’s Ecofiltro bag plants publish real-time carbon footprint dashboards, allowing brands to market verified sustainability stats. This transparency directly impacts SEO performance - Google’s E-A-T guidelines prioritize content demonstrating ethical business substantiation.