When sourcing custom bags, brands often face a puzzling question: Why do seemingly similar products from different suppliers vary so drastically in quality? The answer lies in the intricate details of material selection, craftsmanship, and design philosophy. As a brand targeting the premium market, understanding these nuances is critical to ensuring your products stand out. Let’s explore the five core factors that define quality differentiation in bag manufacturing, usingthe example of a PVC transparent beach backpack—a product where subtle choices make all the difference.

Not all materials are created equal. For instance, while two suppliers might use PVC for a transparent beach backpack, the quality of the polymer resin and additives determines clarity, flexibility, and resistance to creasing. At OSAMIC BAGS, we prioritize Grade-A PVC with superior transparency, ensuring the bag remains crystal-clear even after prolonged use. Lower-tier suppliers often opt for cheaper, recycled PVC blends, resulting in a cloudy appearance and premature wrinkling.

Similarly, components like straps matter. Our backpacks feature thick, reinforced webbing that withstands heavy loads, while competitors may use flimsy materials to cut costs. This difference becomes evident during stress tests and long-term use.

A transparent PVC bag isn’t just a container—it’s a statement. Unlike casual nylon backpacks, transparent designs demand structural integrity to maintain shape and visibility. Our production process includes internal reinforcement frames and seamless welding techniques to prevent sagging. Cheaper alternatives often skip these steps, leading to a crumpled, unprofessional look.

Moreover, stitching quality is non-negotiable. We employ nylon threads and a 7-stitch-per-inch standard for seams, ensuring durability under retail weight tests. In contrast, suppliers prioritizing speed over precision may use fewer stitches or inferior threads, risking seam splits and customer complaints.

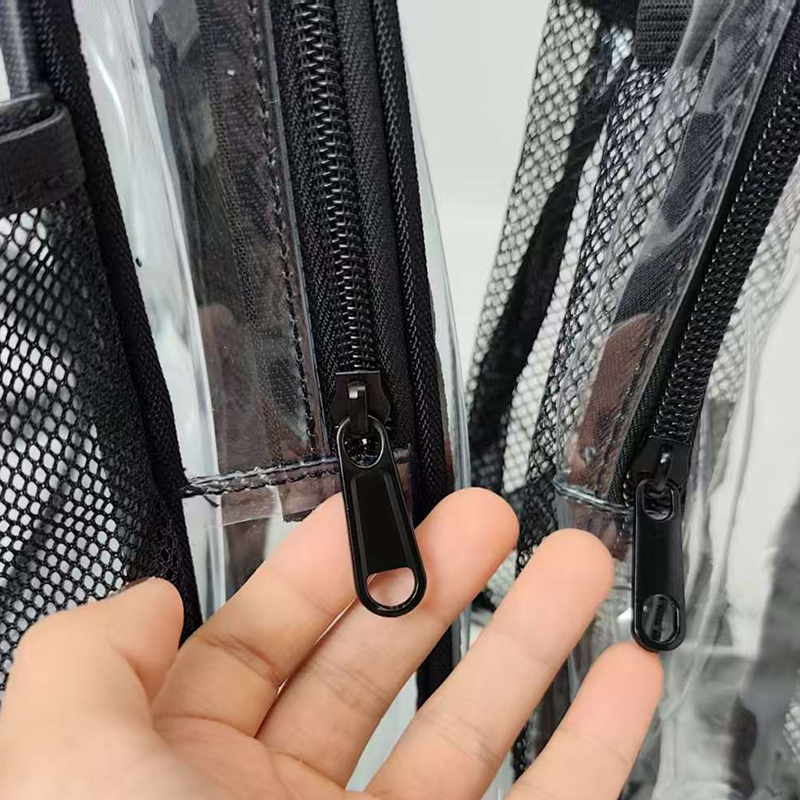

Zippers, buckles, and D-rings might seem minor, but they define a bag’s longevity. OSAMIC BAGS uses heavy-duty, corrosion-resistant hardware tailored to the bag’s design. For example, our PVC backpacks feature reinforced zippers that glide smoothly even under saltwater exposure. Budget-focused suppliers often opt for lightweight, low-grade metals that rust or break under stress.

Even the mesh fabric lining matters. We select high-density, soft-touch mesh for internal pockets, enhancing both functionality and tactile appeal. Lower-quality suppliers might use sparse, scratchy mesh to save costs, undermining the user experience.

The global bag manufacturing industry is highly fragmented, with many small workshops prioritizing low prices over quality. For instance, some suppliers in China’s Pearl River Delta region compete by slashing material costs and simplifying processes, leading to inconsistent outputs. At OSAMIC BAGS, we adhere to a premium OEM/ODM model, investing in R&D and rigorous quality checks to ensure every product aligns with brand standards.

This approach contrasts sharply with factories that cater to mass-market, low-margin orders. As noted in industry reports, price wars have driven some suppliers to offer PVC backpacks at half the production cost of quality-focused manufacturers—a race to the bottom that sacrifices durability and aesthetics.

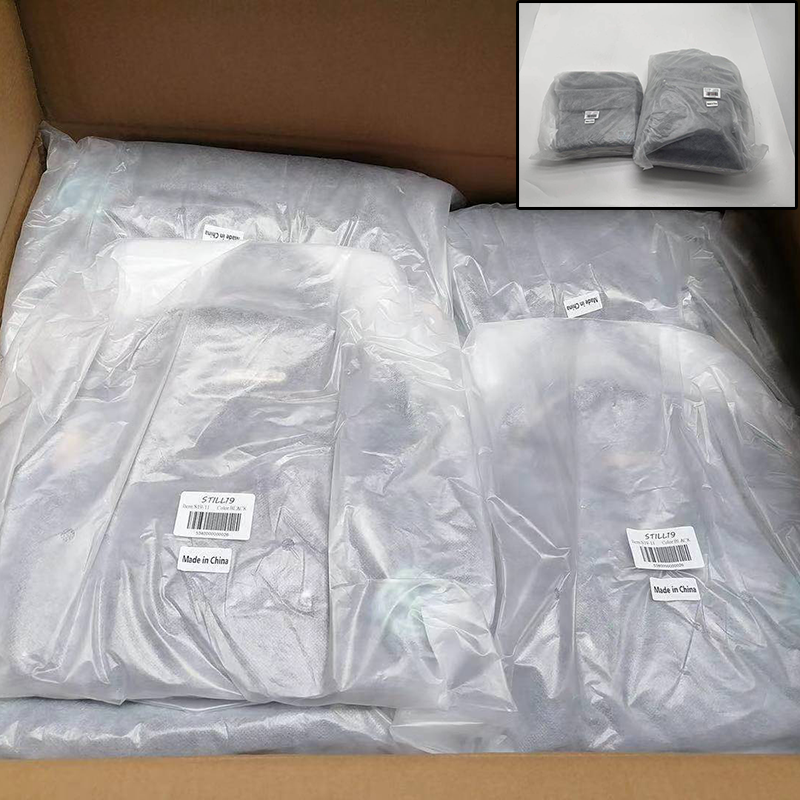

First impressions matter. For high-end markets, we include custom-branded non-woven dust bags and protective plastic sleeves, transforming the unboxing process into a luxury experience. Competitors targeting budget segments often skip these touches, delivering products in plain packaging that lacks brand identity.

In an industry where “good enough” is often the norm, OSAMIC BAGS stands apart by prioritizing quality transparency, innovation, and brand alignment. Whether it’s selecting top-tier PVC, perfecting stitch density, or designing premium packaging, every decision reflects our commitment to elevating your brand’s value.

Why settle for less? If you’re seeking a supplier that transforms functional bags into premium products, contact OSAMIC BAGS today. Let’s craft designs that resonate with your audience—and withstand the test of time.